All four of the Malhamdale mills were initially set up to spin cotton into yarn, though the Malham mill seems to have a very short life and Scalegill only employed a few workers by the latter half of the 19th centuy, as evidenced in the census. Airton and Bell Busk mills were both very productive up until the start of the 20th century, although the Bell Busk mill had turned to spinning silk thread at about the time of the “Cotton Famine”. The local mills were only engaged in spinning cotton into yarn, no weaving of cloth ever took place in the Dale’s mills.

Cotton

Cotton is a most versatile textile fibre and comes from the soft, fluffy fibre surrounding the seeds of cotton plants. It is these fluffy fibres that help to distribute the seeds in the wind, that can be drawn out and spun into thread. The genus the plants belong to is native to tropical and subtropical regions around the world, including the Americas, Africa, India, and Pakistan and cotton had been known in Northern Europe since the 14th century, being brought from the Middle East where it was cultivated. Initially it was mixed either with linen or worsted yarn. By the end of the 16th century, cotton was being cultivated throughout the warmer regions in Asia and the Americas, but production used hand spinning and weaving techniques little changed for centuries. By 1750 some pure cotton cloths were being produced in Britain, but the Industrial Revolution during the late 18thC was in full swing and rapidly provided the new tools required to mechanise production and provided Britain with a new and important manufacturing industry, with cotton textiles soon emerging as a leading export.

Cotton processing in India declined during British expansion in India during the late 18th and early 19th centuries, the Empire had a captive market and India was increasingly forced to supply only the raw cotton to Britain and to purchase manufactured textiles from Britain.

By the 1840s raw cotton came from plantations in the United States because it was cheaper and stronger, with “King Cotton” quickly becoming the mainstay of the southern American economy, with cultivating and harvesting cotton becoming the leading occupation of slaves. During the American Civil War (1861-1865) the Union blockaded the southern ports making the cotton buyers look to Egypt for supplies. This is sometimes referred to as the Cotton Famine and many cotton mills closed leaving people with no work. The lack of American cotton was only one of the causes of the Cotton Famine, the mills also closed because too cloth much cloth was being produced before the crisis. It was around this time that Charles Rickards bought Bell Busk Mill turned it from spinning cotton to silk. Once the Civil War was over, America again became the main source causing financial problems in Egypt.

The cotton bolls, once harvested from the plants are subjected to Ginning, a mechanical process using a machine called a Saw Gin to separate the fibres from the seeds and then the raw cotton is compressed and packed into bales weighing about 500lbs (200kg) at the plantations.

The Spinning Process

A spinning mill employs three main processes to convert these basic fibres into yarn or thread, to further clean, straighten and align the fibres, and then finally bind them together by twisting into a thread.

1. Opening and Cleaning

When the bales are opened at the mill, the batches of fibres from a number of similar types of bale are mixed together. This blending serves to minimise any slight variations between the bales; this commonly occurs with natural fibres such as cotton. At this stage the cotton is still quite stiff and still contains some seeds, soil and leaves which are removed by a combination of mechanical and pneumatic methods. The process is referred to as Scutching and Willowing and was avery dusty operation. The cotton is placed on a wire frame in the machine and beaten with parallel blades to open the fibres of the cotton and help separate the cotton from the waste, which falls through the wire. The cotton then goes through a revolving spiked drum and powerful fan is used to separate the fine cotton wool from the waste, the result being a sheet of fine cotton wool with few impurities left, called lap.

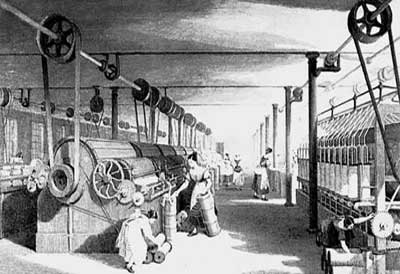

Carding machines.

2. Carding and Drawing

The Carding process is now used to remove as much as possible of the remaining impurities and to align the cotton fibres ready for further processing. This is achieved by using a carding drum, a small roller called a stripper takes the cotton from the worker and feeds it into the carding drum where the fibres pass between the drum and its cover, both of which are covered with sharp wire teeth. The resulting thin sheet of fibres then pass through a funnel and rollers, becoming long, loose strands called slivers or tows, which are collected in tall cylinders.

After carding the soft rope of tow needs to be stretched and thinned using the processes of drawing and roving. This is done by drawing them between a series of pairs of rollers, each pair running slightly faster than the one before. This stretches and consolidates the cotton and makes it thinner and thinner. Once this is done the cotton is twisted to make it stronger and the result, called Roving, is then wound onto a bobbin or spindle.

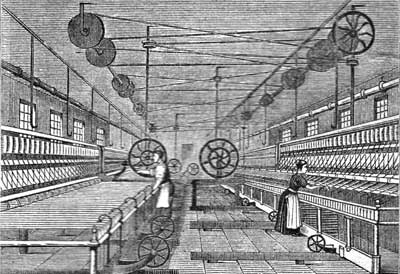

Mule spinning machines.

3. Spinning

Spinning is used to turn the roving into yarn of varying thickness depending on its final use. This took place on a Mule Spinning machine draws the cotton cord from spindles between rollers of varying speeds, drawing it out and twisting it into an even finer thread, before winding the finished yarn onto a bobbin.

Spinning took place in a hot and humid room, which required light clothing and 3 people would operate two machines. In an 1854 survey a worker reported “My work was to put in the roving on a pair of mules containing 256 spindles. It required three hands, a spinner, a fore side piecer and a back boy [doffer], to keep that pair of mules in operation.”

Other Processes

The cotton spinning mills also carried out other processes which included checking the yarn for imperfections and winding it onto large cones sometimes called a “cheese” if they were for warp threads, or smaller “cops” if they were for weaving shuttles. Yarns could also be folded and twisted together to make a heavier, stronger strand such as sewing threads and heavier industrial yarns.

If a mill was involved with a weaving shop, it might also undertake preparation of the Warp threads, the ones that run the entire length of a piece of cotton cloth, for the weaving shed. Warping is the process where a large number of warp yarns are wound onto long rollers called beams, each warp thread an equal distance apart, ready for the prepared beam to be transferred to the weaving loom.

Occupations

Listed here are the job titles you will encounter when looking at the census entries for the workers in Malhamdale’s cotton spinning mills, with a brief description of what the job entailed.

| Job Title | |

| Beamer | Winds the warp threads onto large rollers (beams) for loading onto power looms. |

| Blower feeder | Feeds the fibres into a willowing machine. |

| Carder | Carding machine operator. |

| Cleaner | Operates scutching / willowing machines. |

| Cotton mixer | Mixes batches of fibres from a number of bales to minimise variations. |

| Creeler / Quiller | Replaces full bobbins with empty ones on a spinning machine, a job done by children as young as 8 years old in Malhamdale. (A creel is the metal spindle or bobbin, otherwise known as a Quill |

| Doffer | Unloads full bobbins from a spinning machine [the same job as a creeler?]. |

| Doubler | Operates a machine used to twist together strands of cotton roving or sliver. |

| Drawer | Runs a machine in which several strands of sliver are combined into one strand and drawn out so that the combined strands approximate the weight and size of any one of the original strands. |

| Frame tenter | Someone who looks after spinning frames. |

| Half-timer | A child who spent half the day at school and the other half earning money in a mill. Typically they would start work at 6am, work in the mill until 1pm, then go to school until 4pm. |

| Jack frame tenter | Operates a machine for lightly twisting the roving as it leaves the carding machine. |

| Overlooker | A foreman or overseer. |

| Piecer | Mends broken threads during spinning. |

| Roller Coverer | Recovers and refurbishes the rollers used in spinning and drawing machines |

| Rover | Operates a machine used to prepared the carded fibre lap into rolls of roving, which is the loosely twisted strand of cotton fibres from the time it leaves the slubber until it goes through the spinning frames and becomes yarn. |

| Scutcher | Runs a machine to clean and separate the usable cotton fibres from the woody seeds and leaves in the raw cotton. |

| Self-actor minder / mule spinner | Operates a spinning machine. A self-acting spinning mule could be operated by semi-skilled personnel. |

| Slubber | Removes the “slubs” or imperfections in the roving. |

| Spinner | Operates spinning machine to make thread, running one or more usually two spinning machines facing each other, each with many spindles. |

| Stripper | Someone employed to feed cotton into and remove the rubbish from the carding machines. |

| Tenter | Someone who looked after something e.g. an engine tenter looked after a steam engine. |

| Twister | Runs a machine for twisting yarns and threads together to make thicker stronger yarn. |

| Warper | Someone who prepares the warp threads onto large rollers called beams, ready to load onto the looms. |

| Winder | Runs a machine which transfers the thread from spinning bobbins and winds it onto cardboard bobbins or cheeses forming a cones of thread. |